Machine Vision Products, Inc. (MVP), a pioneer in advanced imaging technologies, is proud to announce the launch of its newest inspection platform, MVP Aurora. This state-of-the-art system offers automated inspection and metrology for packaged integrated circuits (ICs), ball grid arrays (BGAs), and leaded devices.

Performance

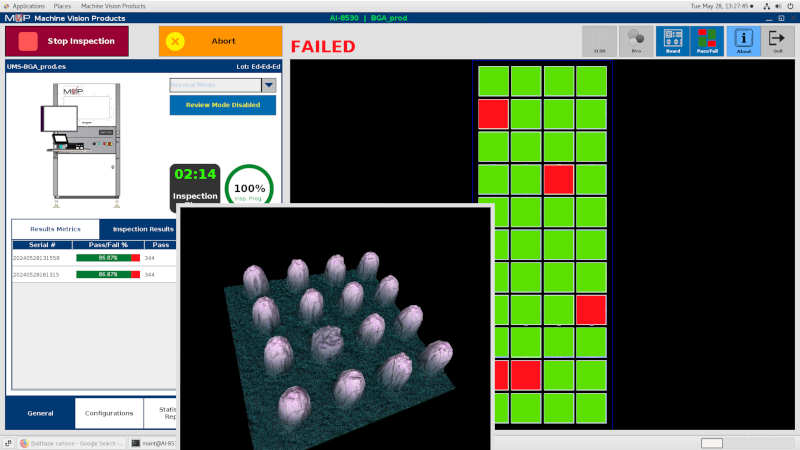

Leveraging over 30 years of experience in innovative Automated Optical Inspection (AOI) design, the MVP Aurora system is engineered to deliver exceptional inspection capabilities through dual technologies. For topside package inspection, the system features high-resolution telecentric optics, enabling precise measurement of device dimensions, inspection of part markings, and thorough surface examination. For the underside inspection of balls and leads, MVP’s shadow-free 3D technology ensures accurate coplanarity and positional measurements.

Designed to provide our smallest footprint, the MVP Aurora employs a Pick-Inspect-Sort methodology for comprehensive multi-sided package inspection. After inspection, defective parts are placed in a defect tray, while good parts are returned to their original tray. This process ensures that the stack of parts loaded for inspection contains only devices that have met all inspection criteria.

MVP’s Aurora system excels in inspecting a wide range of package types, including: Ball Grid Arrays (BGAs), Quad Flat Packs (QFPs), Thin Quad Flat Packages (TQFPs), Chip Scale Packages (CSPs), Wafer-Level Packages (WLPs), Quad Flatpack No-Leads (QFNs), Bump Chip Carriers (BCCs), Land Grid Arrays (LGAs), and more. This makes it an ideal solution for both Outgoing Quality Control (OQC) and Incoming Quality Control (IQC).

MVP’s ePro software facilitates rapid and efficient recipe development, guiding users through the program generation process to quickly create inspection strategies for various devices. To expedite development, data can be imported from CAD, Gerber, or DXF files. The iPro software employs advanced algorithms to perform all inspection tasks with high precision.

The MVP Aurora system supports SECS/GEM with SEMI E142 mapping and offers MVP’s End Lot Summary Reports (ELSR) for exporting tray data. Additionally, MVP’s AutoData SQL system provides robust traceability by saving all parametric and attribute data for products. The database system can also store device images on an individual basis, enhancing traceability and quality control.

To learn more, visit www.visionpro.com.